Why the MCXL is the BEST e.max CAD Mill Out There

So I’ve got your attention. Do I really dare stake claim to a statement as bold as “the MCXL being THE BEST mill out there”? Absolutely not, the MCXL is a terrible mill.

Read the title over again carefully.

Truthfully, the MCXL is a terrible mill, but in my opinion, it is the “BEST e.max CAD mill” out there. It’s loud, its proprietary, and it’s track record is beyond unreliable. Personally, the one I’ve used at our lab since 2012 has gone through 10 motors, a few distribution boards, a fried main board that went POP and billowed smoke, 3 replacement PC towers, and approximately 2-3 chamber doors per year of ownership. Thankfully, mostly all covered under warranty. The Patterson service team member, David, practically lived at our lab at one point. Any more and we probably would’ve had to put him on the payroll.

Now, back to the main point of this post. The MXCL is indeed the best mill for e.max CAD, or blue blocks as they are colloquially referred to. (Even though they look more violet/purple to me personally. What do you think? Am I color blind? Throw your opinion down in the comments!) I didn’t reach this epiphany until a few months ago as a result of our lab purchasing an imes-icore 350i that was ‘capable’ of milling e.max. Notice the emphasis on ‘capable’.

Yes, with the 350i there was an option for a burr smaller than the width of my thumb. And yes, I was able to design in a CAD software package (3shape) that wasn’t intended for ‘clinically acceptable’ same-day restorations while the patient waits in the lobby with a magazine. And yes, I had CAM software that could nest at different angles and with different sprue sizes!

But when it came time to milling e.max with the 350i, the honeymoon period wore off quickly. Margins chipping, entire crowns breaking loose, poor tool life, longer mill times. How could this be possible? This machine can mill titanium! It weighs 500 lbs! It can tilt at 30 degrees in multiple directions. It can play game of thrones! It can mill everything… Click here to go to my YouTube channel and watch the full review. Now that I’ve finished shamelessly plugging my own content, back to our regularly scheduled programming.

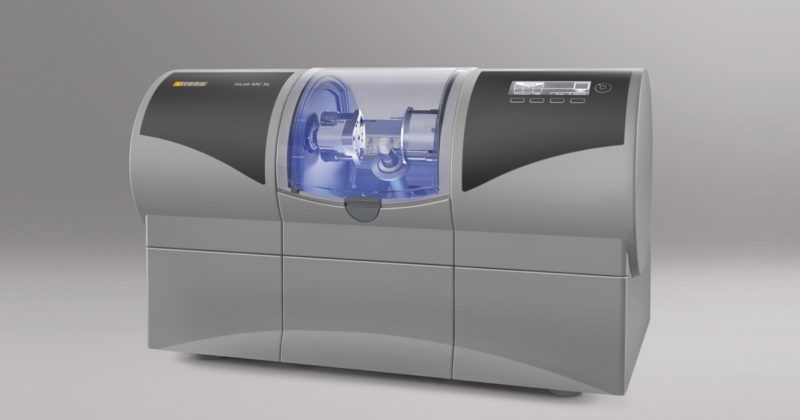

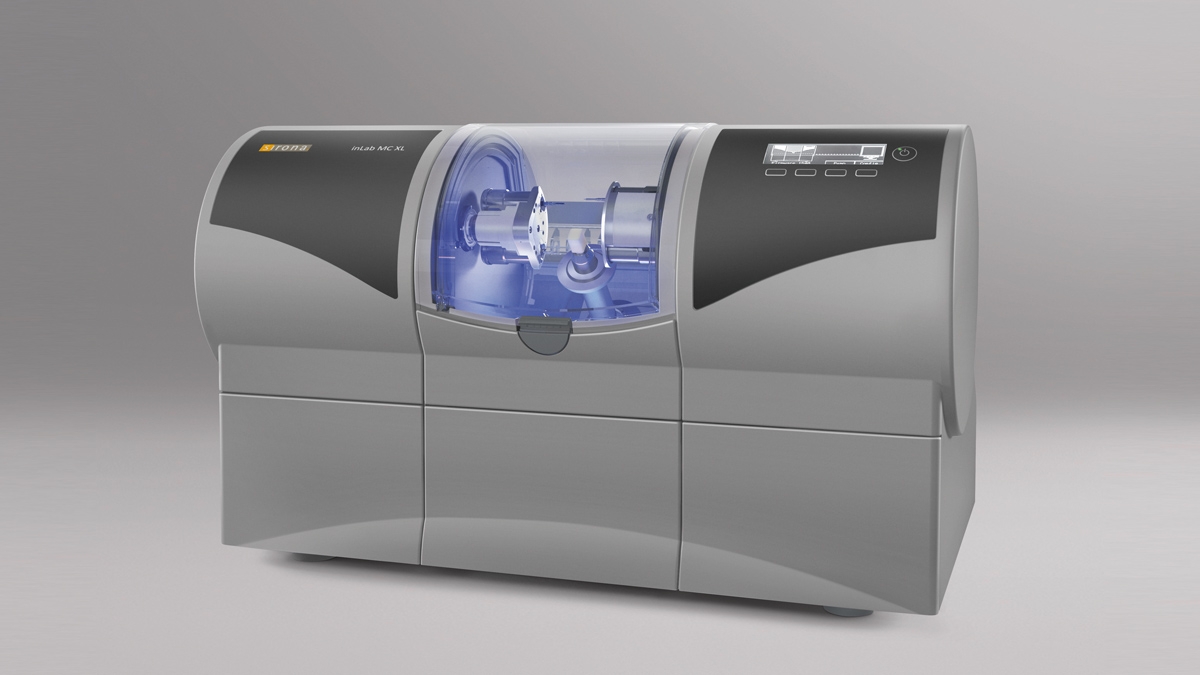

It made me realize that I took that little MCXL money-pit for granted all these years. Sirona, for some odd reason, has had this unfounded vendetta against the dental lab industry and has been actively trying to eliminate the profession by directly targeting dentists as their usual modus operandi since… forever. Let’s set my personal feelings about that aside for a moment, and I’ve gotta say, Sirona did something very right with the MCXL. I can pay due respect to a feat of engineering when it is rightly earned.

My model of the inLab MCXL features 2 motors on each side, the grinding motion and simultaneous action rips through e.max blocks like a 2am run to taco bell does on its way through your digestive system. The torque driver supplied with the machine is dialed in to a specific setting to eliminate vibration in the mandrel. It took me almost 8 months before I thought to apply the same torquing principle to the 350i’s glass block adapter… which did indeed significantly reduce chipping rates!

Calling the MCXL a “Mill” is actually inaccurate. It is a grinding machine. The way that it operates compared to a standard mill is completely different. This gives it an edge over mills with “wet options” because it is a purpose built tool for a specific task. Yes, there are other purpose-built grinding machines out in the market like the Roland DWX-4W, the CORiTEC 140i, The IOS Technologies Ts150, Kavo Arctica, AG Ceramill Mikro IC, Carestream CS3000, VHF N4, and the Planmeca PlanMill40S. But I haven’t personally tested any of those machines to comment on their respective e.max grinding abilities.

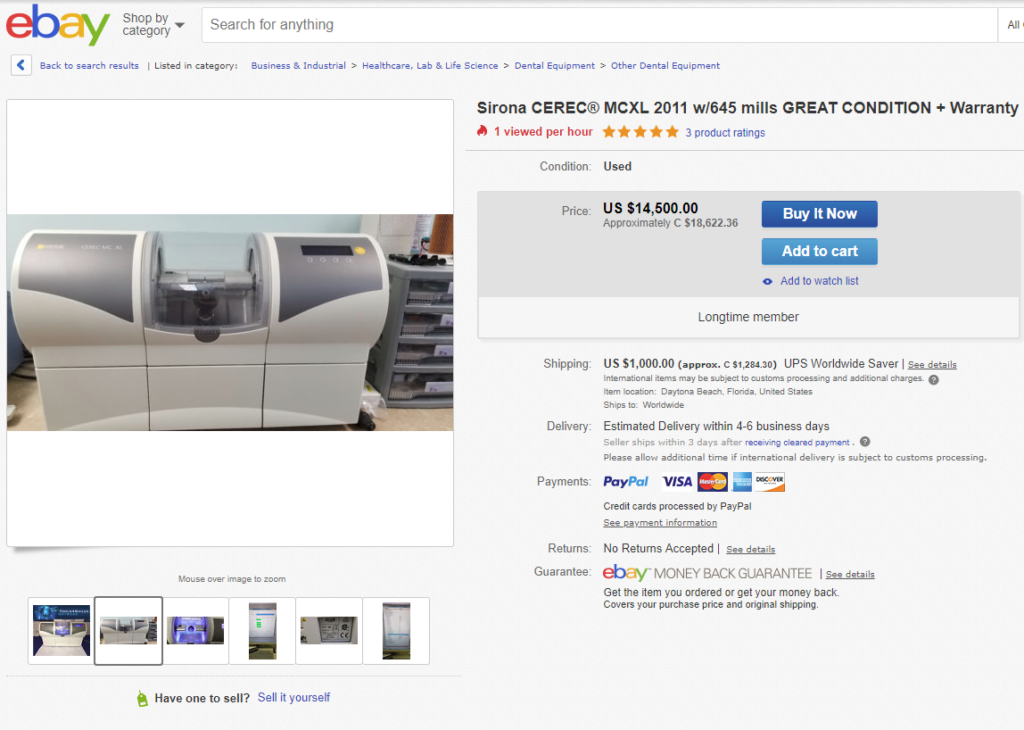

Taking it a step further, when the coolant that is used gets mixed with leftover grindings from the e.max, it amounts to nothing less than what I’d like to describe as ‘liquid sandpaper’. This is catastrophic for the seals and gaskets it just destroys them. Those cheap plastic MCXL chamber doors never stood a chance. My newfound respect was confirmed earlier this year when I had a chance to chat with a bunch of colleagues. They also mill e.max cad blocks, but on Wieland Selects, Rolands and even on DMG Ultrasonics. The consensus is that any and all CNC machines that mill e.max are prone to rapid deterioration. It’s simply the nature of the beast. The MCXL just happens to mill e.max much more quickly and produces desirable margins more reliably. Finally, the Pièce De Résistance, and what makes the MCXL stand out in its specific category as opposed to other purpose built wet grinders: How popular it is, and as a direct result of that, how cheaply one can come across a unit second hand. The used market for MCXLs is ripe for the picking.

As much as dentists like to try their hand at eliminating lab bills from their practices, many of them lack the time/staff/patience/know-how to operate a mill effectively, and their MCXL’s end up sitting in a corner collecting dust. Eventually, those lightly used machines end up on the second-hand market. You could purchase an entire farm of second-hand MCXL units to mill glass blocks all day long for the fraction of cost of some other options I’ve previously listed.

Picture this: you pick up an inLab cam license from Sirona, and then network together a farm of these machines. Disclaimer: there would be no automation, occlusal anatomy detail would suck, and those who dare to enter the room would probably be required to wear noise-cancelling ear protection from the screaming of those motors.

But churning out units at an average of 15 minutes a piece and margin reliability that beats out half-million dollar, 15-kilowatt behemoths. You’ve got a golden solution for a high-volume production environment to take care of such a challenging material. And since you can pick up used ones on eBay for next to nothing. If one is irreparable, just hop on an auction site and pick up a slightly used replacement. Granted, if everyone did this, we’d simply drive up the price in the second hand market and do what mining cryptocurrency has done to the cost of graphics cards.

But for that particular enterprising individual, who has just the right amount of demand, this solution might be a good fit. Personally, I find my volume of milled e.max to be declining so this MCXL farm wouldn’t be a good fit for me. Newer generation zirconias that are being released now, are rivaling e.max in translucency and overall appearance, while also being much easier to mill and touting higher strength figures.

If someone does decide to venture into this MCXL farm idea, we’d love it if you could share some pictures of your progress/setup! One piece of advice though: make sure you have a very capable service team member on your staff at all times, those machines are notoriously unreliable. The MCXL may be a terrible mill, but in my opinion, it is the BEST e.max CAD mill out there!

Have any stories about the unreliability of this machine that you’d like to share? Or do you disagree with the opinions? Throw your thoughts down in the comments section and let us know what you think about the MCXL.